| Difficulty Level: |

|

fairly hard |

Parts and Tools

- MDF or timber (200 x 200 x 12mm)

- Timber (180 x 40 x 40mm)

- 4 x Plywood (30 x 30 x 5mm approx)

- Drill and 4mm wood bit

- 2 x 4mm sockets

- 3V motor (rectangle type)

- Plastic coated insulated wire (1m)

- Wire strippers/cutters

|

- 1 x propeller (Timstar)

- PVA wood glue

- 1" thin nails

- Tenon saw

- Ruler

- Soldering iron and solder

- Glue gun and glue

- 4 x small 'G' clamp

|

Instructions

This model wind turbine is very similar in construction to the colour wheel also featured in this section. It consists of a small 3V motor which acts as a dynamo, creating electricity when the propeller is turned. The model can be connected to a digital or analogue voltmeter so that the electricity produced can be shown.

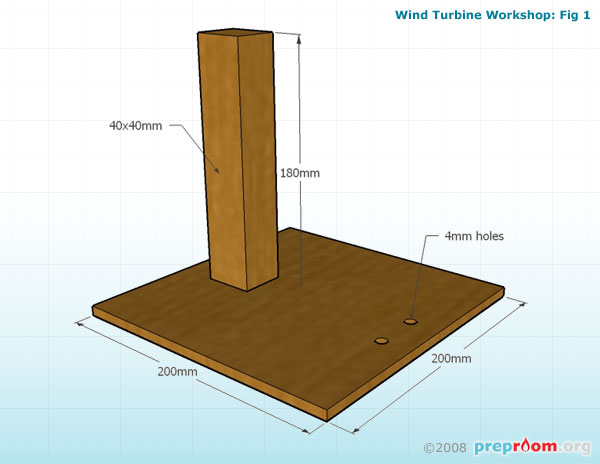

Fig 1: Base of model

Fig 1 shows the main base of the model. The size can be adjusted to suit your needs, in fact the measurements of the entire model may be changed if required. Any type of MDF or blockboard can be used for the base. It needs to be sturdy enough to support the upright column securely.

The upright piece needs to be firstly glued in place using PVA wood glue and also secured from below using 3 or 4 small nails. Use thin nails as not to split the wood along the grain.

Two holes need to be drilled into the base opposite the upright column. The holes should be big enough to fit the 4mm sockets. Most require a 4mm hole but others require a larger 6mm hole so before drilling, check which type of socket you are to use.

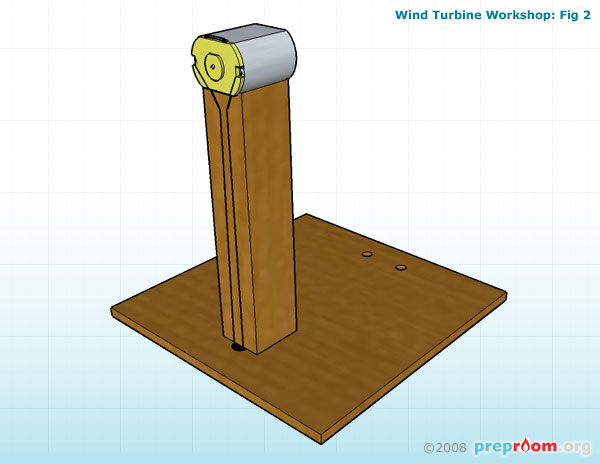

Fig 2: Attach motor to column

Fig 2 shows how the motor should be attached to the column using a glue gun. Ensure that the glue does not enter the motor itself through the air holes located on the motor case. A 4mm hole needs to be drilled just behind the column so that the wires from the motor can be fed though. When the motor glue is set, solder a length of plastic coated insulated wire to each of the motor terminals and feed them down the column, through the hole and under the base. These loose wires may also be glued into place using the glue gun. Try to keep them fairly taught.

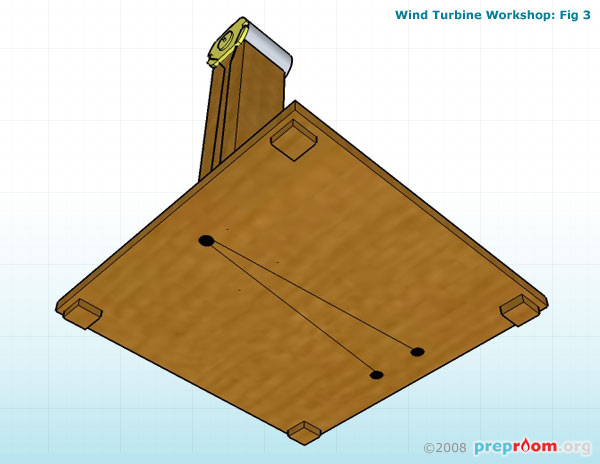

Fig 3: Wires underneath base

Fig 3 shows the underside of the unit with the wires pulled taught and glued in place. It also shows the four feet attached. Four pieces of plywood should be glued onto the base, one in each corner, using PVA wood glue and held in place with 'G' clamps until dry. Ensure the feet are thick enough so that when the unit is turned over the socket terminals do not touch the surface where the model is placed.

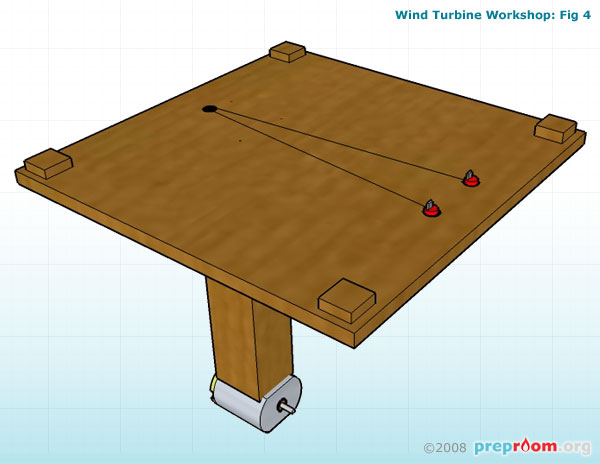

Fig 4: 4mm sockets in place

Fig 5: 4mm sockets in place

Fig 4 and fig 5 show how the 4mm sockets should be pushed through the holes in the base and soldered to the free ends of the wires connected to the motor. Try to cut the wires so that they remain taught and therefore do not get caught on anything if the unit is moved. The sockets should fit tightly into the holes but if they seem slightly loose, glue them into place with a glue gun.

Fig 6: Propeller in place

Fig 6 shows the propeller in place. These can be purchased from Timstar Lab Supplies and are designed to push onto the motor shaft to provide a secure fit. Various propeller designs can be found in model shops but make sure they will fit the motor shaft before purchasing. Alternatively students may wish to construct various designs themselves from plastic sheets. Blu-Tak is good for helping to hold these home-made propellers in place.

Once constructed, this model wind turbine may be connected to a voltmeter using standard 4mm wires and the propeller turned using a hairdryer. Typically, voltages of around 3-6V may be achieved if the blades turn fast enough. The model can also be used in reverse by connecting to a 3V source such as a labpack. The motor will turn the blade in either direction depending on the polarity of the power source. Only connect to D.C power, never connect the model to an A.C source as this may damage the motor.

Disclaimer

Before attempting any of the construction projects featured on this website, ensure you have, and know how to use, the appropriate tools, components and safety equipment and are competent to undertake the project. These guides are for information only and we hold no responsibility for any accidents, injuries or damage caused by the use or misuse of any equipment, project or information contained within this website. In short - use common sense and stay safe!