When heating is required to produce a gas, when making ethane for example, the gas remains hot as it bubbles out of the delivery tube under water. The problem is that as the gas cools, it contracts, sucking water back up the delivery tube.

The Bunsen valve is essentially a one way valve used to stop this suckback problem. It is simple and cheap to make and works very effectively. This guide shows how.

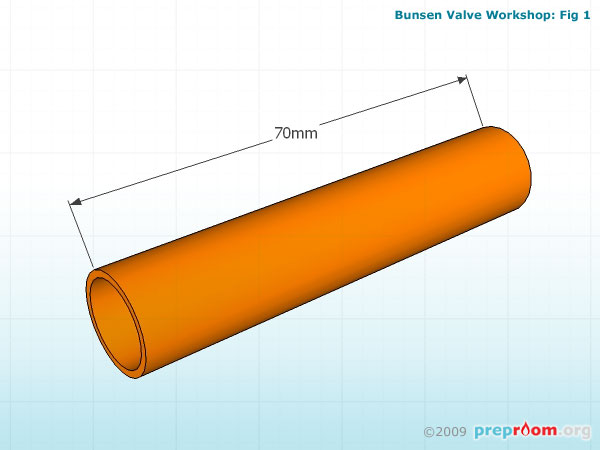

Fig 1 shows a length of thin rubber tubing. This tube needs to be a suitable diameter as to fit on the end of a delivery tube. The length can be from 40-70mm.

Fig 2 shows the delivery tube in place. Ensure that this is inserted far enough into the rubber tube as to be secure and not allow gas to escape.

Fig 3 shows the glass rod piece in place at the opposite end to the glass tube. This rod piece needs to be 30-40mm long. When cutting the piece, heat each end in turn to remove any sharp edges. Again this rod should be pushed into the rubber tube far enough so that no gas can escape around the join.

Fig 4 shows the completed Bunsen valve. The final step is to cut a slit in the top of the rubber tube. This cut needs to be straight and clean and approximately 10-15mm long. This will allow the gas to escape under pressure but will close if suckback occurs.

Please note: When cutting and heating glass rod, please ensure you are competent to do so and are well aware of the safety implications.