This guide demonstrates how to construct a simple pressure sensitive switch that can be integrated into existing circuits or used in conjunction with a lamp and a power supply to create a simple switch circuit.

The model is a larger-than-life example of commercially available pressure switches which are often used in burglar alarm systems. As pressure is applied to the top layer of foam, the contacts inside (which are normally separated by foam strips) touch each other and as such can be used to switch a circuit.

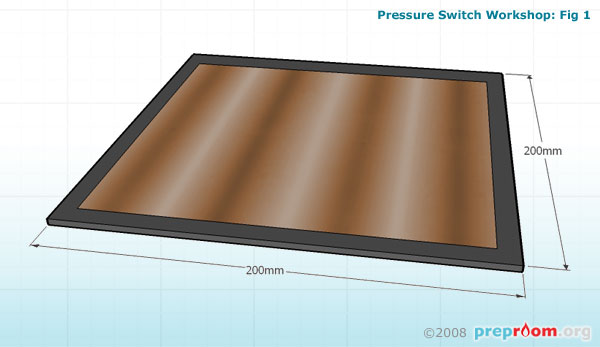

Fig 1 shows a square piece of foam with a smaller square of copper foil glued centrally on top. The foam can be purchased through craft suppliers and is usually sold by the sheet fairly cheaply. The foam needs to be approximately 3-6mm thick and can be any colour available. The copper foil is available through most lab suppliers and sold by the roll. It needs to be thin enough to bend easily. When cutting the foil beware of the very sharp edges. PVA glue provides a fairly good join but allow to dry completely before use.

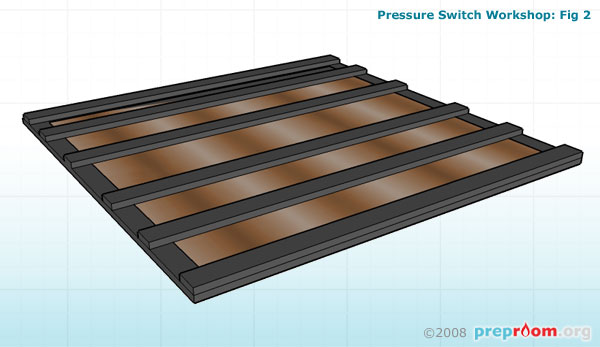

Fig 2 shows strips of foam glued across the surface of the copper foil. These strips need only to be approximately 20mm across. They are to support the top layer and keep the two copper surfaces separate until pressure is applied. Ensure that gaps of about 30mm are left between foam strips.

Strips can easily be cut using a craft knife or scalpel and metal ruler.

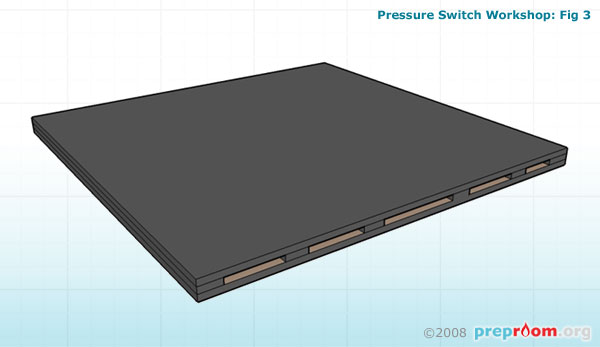

Fig 3 shows the top layer in place. This layer should be exactly the same as fig 1, consisting of a square of foam with copper foil attached. The top part should be glued using PVA where the foam parts touch. Make sure you do not get glue on any copper foil part as this may affect the conductivity of the metal surfaces.

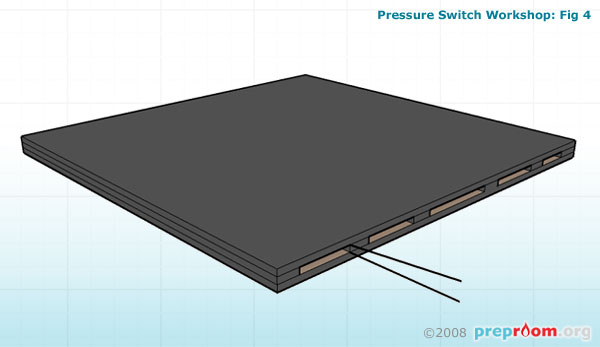

In fig 4, two lengths of plastic coated copper wire have been stripped of about 30mm of insulation and pushed into the gaps between foil and foam on both top and bottom. The wire needs to make good contact with the foil sheets and so a small piece of aluminium foil may be used to pack the wire tightly onto the foil. This is the weak part of the model as the leads are easily pulled from the device. Alternatively crocodile clips may be used to connect the wire but make sure they do not come into contact with one another as this will short the circuit.

The free ends of the wire may be connected to the circuit as in fig 5. In this simple setup, the pressure switch turns the lamp on when enough pressure makes the two copper foil sheets touch within the switch, closing the circuit.

Do not exceed 12V D.C using this switch.